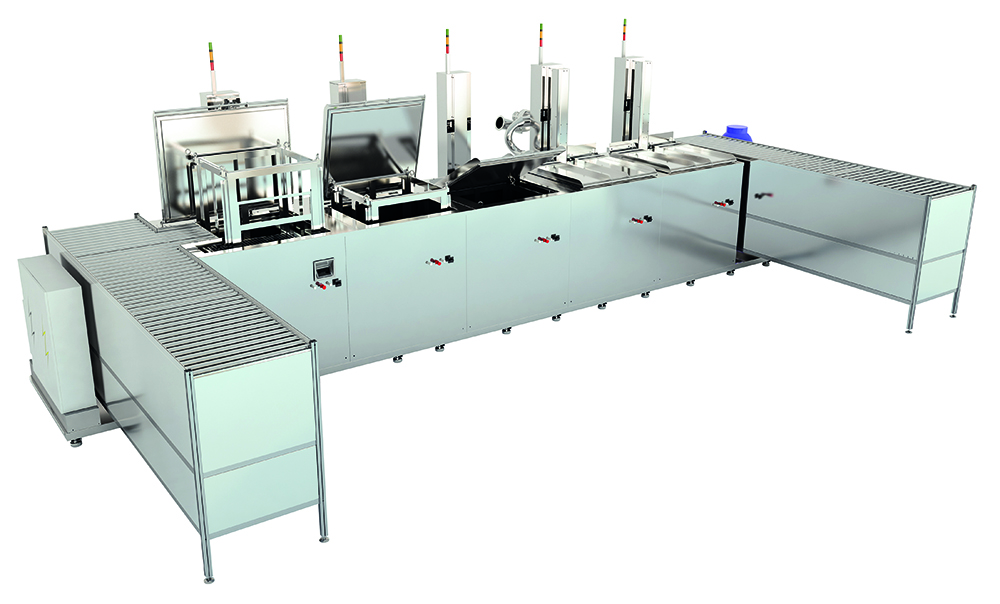

MULTISTAGE SYSTEM

UltraTecno offers a wide range of modular technical solutions to build up a custom complete system for each industry cleaning requirements. Each line is adjusted and configured with the desired wash, rinse and drying stages according customer needs.

Flexible, reliable and robust systems starting from 100 liters tank capacity up to 15.000 liters for each stage. Multistage dimension tank is the same as ACM / ICM dimensions and could be complemented with RT Rinse Tanks and Dry Drying Tanks.

RT TANK

Rinsing is as important as cleaning. It will remove detergent and remaining dirt from parts. Air bubbling jets increase rinsing effectiveness. Water must be keep clean, so active carbon filter is highly recommended. Number of additional rinse steps in reverse cascade arrangement will be determined according to cleanliness level requirements. Use of pure demineralized water at final rinsing stage will allow best final results.

Ultratecno offers a complete range of rising RT tanks. Optionally it can be equipped with bubbling, heating, filtering system, automatic lid, lifting platform, automatic filling or osmosis plant.

DRY TANK

The DRY tank with hot air cyclone quickly removes water from freshly cleaned. Adequate thermal insulation ensures the lowest electrical consumption.

Ultratecno offers a huge range of DRY tanks to complement ACM / ICM ultrasonic tanks . Optionally the tray can be equipped with automatic lid and lifting platform.

Multistage lay-out allows easy parts handling by using overhead cranes, custom automated manipulation systems or robotized systems. Customized baskets can be used to ensure perfect integration at customer manufacturing or maintenance process.

Ultrasonic Multistage systems are ideal for customers searching for repetitive cleaning of parts during their process.

1 ULTRASONIC CLEANING

Our powerful cavitation will loosen dirt on parts. Bath includes water and specific detergent (5-15%) for each application. Heating up to 90ºC increases overall performance.

2 WATER RINSE

Rinsing is as important as cleaning. It will remove detergent and remaining dirt from parts. Air bubbling jets increase rinsing effectiveness. Water must be keep clean, so active carbon filter is highly recommended.

3 ADDITIONAL WATER RINSE STAGES

Number of additional rinse steps in reverse cascade arrangement will be determined according to cleanliness level requirements. Use of pure demineralized water at final rinsing stage will allow best final results.

4 PARTS PROTECTION

Passivation agents bath will protect your parts against corrosion. A complete range of products is available depending on customer parts material and temporal protection range desired.

5 DRYING

Hot air cyclone chamber quickly removes water from just cleaned parts, so they are ready to continue their manufacturing process. Proper thermal insulation ensures lowest electrical consumption.

- Pneumatic or hydraulic platform lift for parts swing to increase effectiveness while cleaning or rinsing stages.

- Cartridge or bag filtration for ultrasonic tank.

- Automatic water refilling.

- Automatic Liquid Detergent Dosing System .

- Detergent preparation (pre-mix) tank.

- Automatic Oil Separation for US tank.

- Air bubbling or water jets for rinsing tanks.

- Active carbon filtering for rinsing stages.

- Sprinklers system for parts rinsing while being extracted.

- Osmosis plant for demineralized water generation for final rinsing stages.

- Safety enclosure for loading system.

- Customized basket and lifting beams.

- Steam extraction to ensure healthy plant environment.

- Loading/unloading conveyors, manual or motorized.

- Ultrasonic sets at rinsing stages for special applications.