Ultrasounds are sound waves with frequencies above the human auditory range (20 – 100 kHz). The ultrasound applications are based on the physical phenomenon of cavitation

which may be induced in any liquid medium.

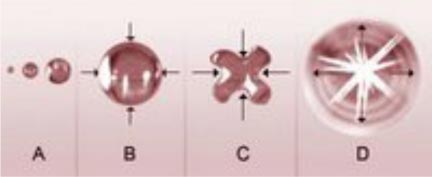

The sound waves cause the microscopic bubbles present in the natural liquids to expand (during phases A and B of low pressure) and contract until they implode (during phases C and D of high pressure). The formation and implosion of bubbles (cavitation process) is produced thousands of times per second.

ULTRASONIC CAVITATION EQUIPMENT

UltraTecno specializes in the distribution of a multitude of ultrasonic cavitation equipment for industrial companies. With a broad technology base, our company has always waged on constant innovation, creating and developing machinery to respond to the current and future needs of our clients. The most prominent applications of this technology include cleaning machines through ultrasonic cavitation equipment, cavitation and ultrasounds cleaning. The technology offers multiple benefits to its users. Ultrasonic cavitation machines guarantee an excellent cleaning process for every type of parts with the maximum level of energy efficiency.

If you are interested in this technology for your industry, UltraTecno will provide you the advisory services you need. Our professional team has the required equipment and technical knowledge for the performance of customized projects. Furthermore, you will rely on the best technical service for the maintenance and repair of machinery. Do not hesitate to contact us if you need more information, we will be delighted to help you.