More than 50 years of experience and knowledge of ultrasonic cleaning systems, dedicated to offering the best solutions and services to our customers.

Our Services

Automotive Series

Our Automotive Series applications are the most efficient way to remove grease, chips, charcoal of any kind of material.

Ship maintenance

Custom applications, even for cleaning and degreasing of large naval elements or energy production plants.

Injection molds

Solutions that eliminate perfectly the remains of all materials from soft metals to all types of plastics and rubbers.

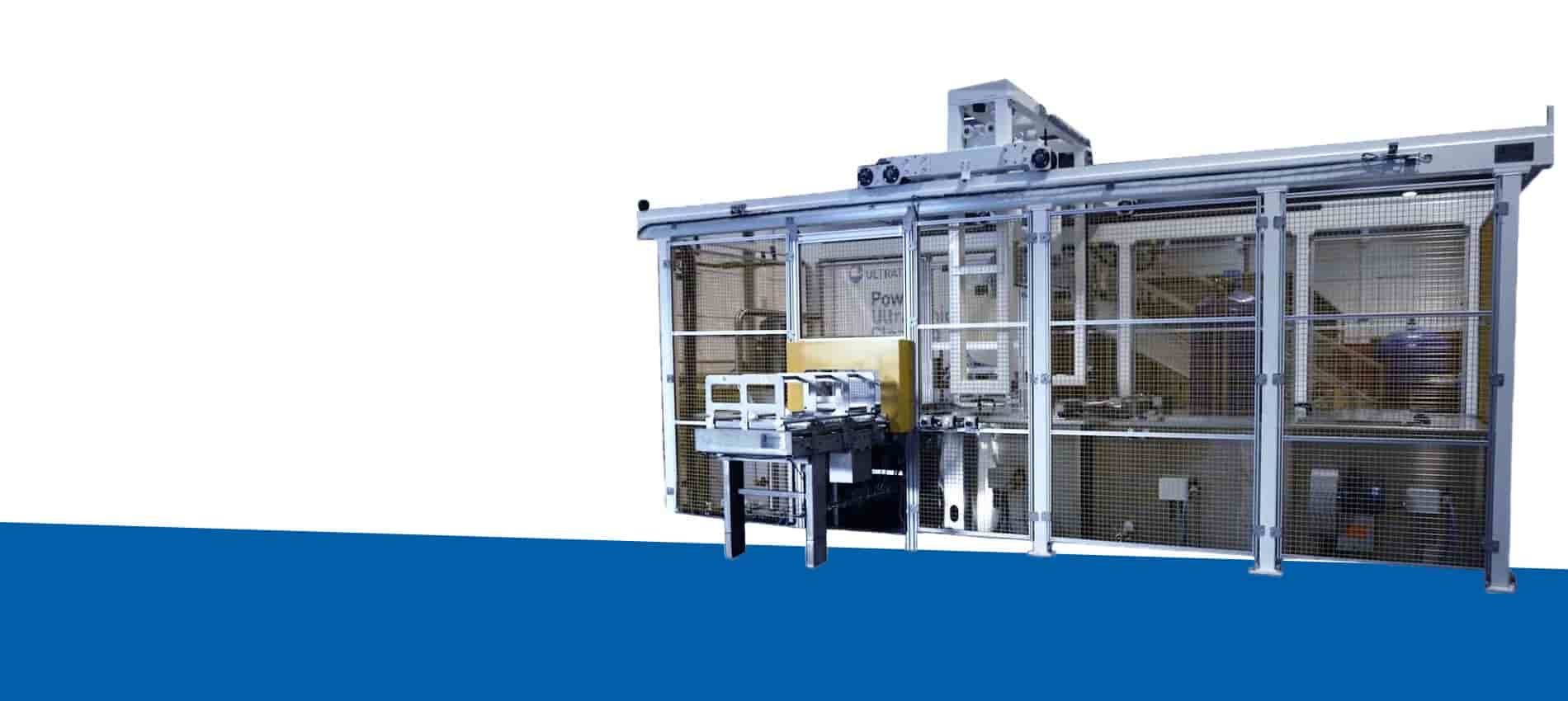

Multistage systems

Commercial applications of recent development with significant technological base and high added value for your process.

ULTRASONIC CLEANER

Welcome to UltraTecno’s official website, leading worldwide company specialized in the design and distribution of ultrasonic cleaning equipment. With more than 45 years of experiencein this field, UltraTecno has always aimed to always satisfy the quality commitment with our clients, offering them the best results.

Since we opened our doors back in 1964, we are at the forefront of the use of new technologies all around the world, offering the best results with our ultrasonic equipment. This objective has prompted us to begin a joint path with a prestigious Australian company whose work, such as ours, is been recognized worldwide by very demanding quality certificates. We currently offer services to a large amount of industry sectors.

Ultrasonic generator

Our ultrasound cleaning systems developed in Valencia are worldwide recognized for the large number of advantages they provide unlike other traditional methods still used today. Our ultrasonic or supersonic cleaner offers very superior cleaning results by saving on consumption costs and labour, and avoiding the use of solvents. Our cleaning systems are the perfect option for a great variety of industrial parts without damaging them. Our Ultrasonic generators also offer a wide range of features. Buy our professional ultrasonic cleaner and ultrasonic cleaner generator by visiting our website.

The quality commitment of our company will last as long as your client wishes. Once you acquire an ultrasonic cleaning equipment from our catalogues, we offer you an excellent maintenance service that ensures the equipment tune-up and maintenance on a regular basis, addressing any incidence in the shortest possible time and with the minimum disturbances.

Finally, if our standard equipment oesn’t meet your requirements, UltraTecno will be delighted to develop a customized solution to answer exclusively to your needs.

Why is ultrasonic cleaning the best option?

It isn’t magic, it’s UltraTecno.

What are you doing to find in this guide?

- What ultrasonic cleaning is and how it works.

- The effectiveness of cavitation and our low-frequency technology for greater cleaning power.

- The advantages of this cleaning system.

- How to save detergent and electricity.

- Industrial applications.

- Patented UltraTecno solutions, the only ones

on the market. - UltraTecno projects.

DO YOU WANT TO BE AN ULTRATECNO OFFICIAL DISTRIBUTOR?

If you are interested: Fill out the form that you will find in the following link and we will contact you..